|

SUPPLY CHAIN |

| << PERSONAL FINANCE ONLINE |

| PORTER’S MODEL OF COMPETITIVE RIVALRY >> |

E-COMMERCE

IT430

VU

Lesson

38

SUPPLY

CHAIN

Supply

chain includes all the activities

associated with the flow and

transformation of goods from the

raw

materials

stage all the way to the end

user. Supply chain can be

broken into three parts,

that is, upstream

activities,

internal activities and downstream

activities.

Upstream

activities relate to materials/services or the

input from suppliers

Internal

activities relate to manufacturing and

packaging of goods

Downstream

activities relate to distribution and

sale of goods to

distributors/customers

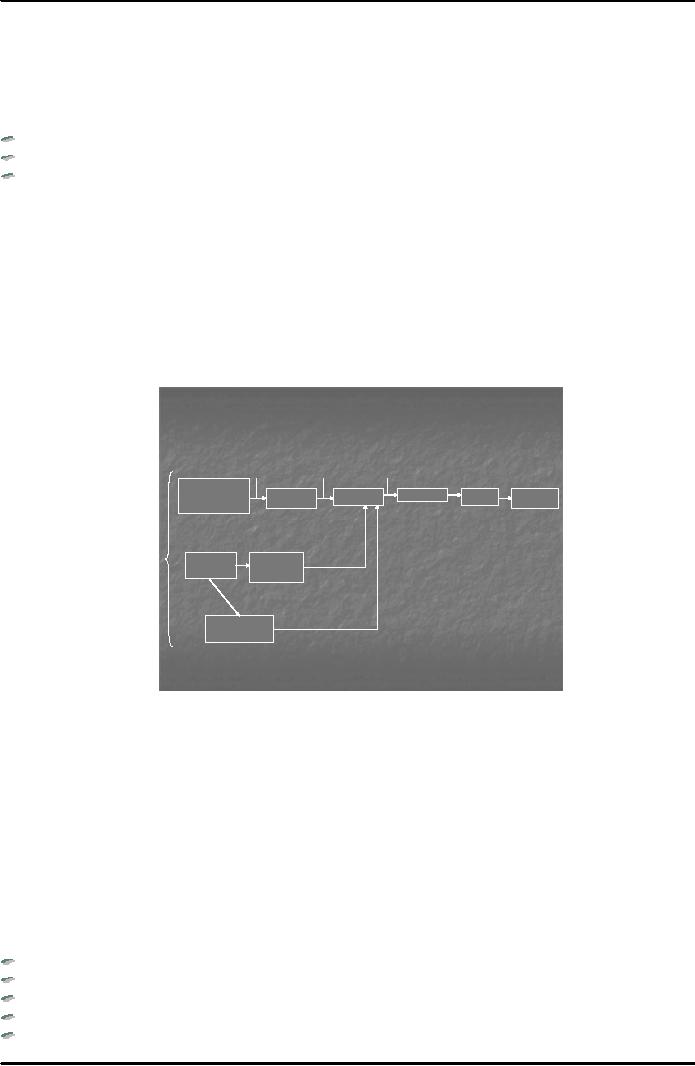

Fig. 1 below

shows a simple example of

supply chain of a milk

processing unit. Note that

milkmen supply

milk

to the processing facility. The

processing business has ordered a

corrugate paper company to

supply

boxes/paperboard

for packaging. The paper

company receives its raw

material from a lumber company

for

manufacturing

boxes. The lumber company

also supplies paper to label

printing business for

making/printing

paper labels. These are

upstream activities. The

boxes and labels should be

available to the

processing

business at the packaging stage.

The milk processing unit

processes the milk, packages it

in

boxes

and attaches labels to them.

These are internal

activities. The packaged

milk is sent to

distributors

who

distribute the same at different

stores from where customers

purchase. These are

downstream

activities.

Supply

The

Milk

Processing

Unit

Chain

Unprocessed

Packaged

Processed

milk

milk

milk

Supplier

of

Processing

Distributors

unprocessed

Packaging

Stores

Customers

Facility

milk

Boxes

Lumber

Corrugate

Company

Paper

Co.

paperboard

Label

manufacturing

Labels

Fig.

1

Supply

chain management

Engaging

and negotiating with suppliers

can be extremely beneficial. The

process of taking active

role in

working

with suppliers to improve products

and processes is called

supply chain management. Today,

firms

are

reaching beyond limits of their

own organizational structure. They are

creating new network form

of

organization

among the members of supply chain.

Supply chain management is

now used to add value

in

the

form of benefits to the ultimate customer at the

end of supply chain. It has

become important for

a

business

to work to establish long term

relationship with at least small number

of capable suppliers.

Internet

technologies and supply chain

Internet

is a very quick and effective tool of

communication. On the other hand, communication is

also a

very critical

element in supply chain

management. Using internet

technology:

suppliers

can share any information

about changes in the customer

demand;

suppliers

can have immediate notice of

any changes in product

design;

drawings/specifications

of a product can be quickly

provided to the suppliers and

vice versa;

processing

speed of a transaction can be

increased;

cost

of handling a transaction can be

reduced;

155

E-COMMERCE

IT430

VU

chances

of errors in entering transaction data

are reduced;

Probably, the

only disadvantage of using

internet technology in a supply chain is

that sometimes it may

prove

to be costly. However, in ultimate

analysis, the advantages override the

cost factor.

With

the help of supply chain

management software, one can

not only manage the internal

processes but

also

processes of other members of the

supply chain. Therefore, it can be

predicted that when and

how

much

of certain product would

need to be produced.

Examples

of technology use in supply

chain

A typical

example of the use of technology in supply

chain management is a company

which is well-known

worldwide

as the largest producer of commercial

aircrafts. It makes a big

effort to keep its

production on

schedule.

Most commercial airplanes require

more than 1 million

individual parts and

assemblies and each

airplane

is configured according to specific needs

of the purchasing airline. Timely

availability of these

parts

must

be ensured otherwise entire production

schedule would be disturbed.

In

1997 the company had to stop

its two assembly operations

for several weeks due to

errors in production

and

scheduling system causing it a

huge financial loss. Thereafter, it

decided to invest in information

systems

in every element of its supply

chain. Involving its

suppliers in the process, it began the

use of EDI

and

internet technology, so that the

suppliers could supply the right

part or assembly at right time

to

prevent

production delay. Now, the

suppliers could get engineering

specifications and drawings before

the

start

of manufacturing using a secure internet

connection, and plan their

own business

activities,

accordingly.

Also, members of the supply chain could

have the knowledge of the completion of

milestones

and

any changes in production

schedule. In two years time, this

approach resulted in reducing

half the time

needed

to complete individual assembly

processes. Thus, instead of

waiting for 3 years the

customer airlines

could

now have the ordered airplane

ready for delivery in 10-12

months. Furthermore, the company

launched

a spare parts web site

for ordering replacement

parts. The site allowed

customer airlines to

register

and

order for replacement parts

through browsers. Soon, the

site was processing 5000

transactions per day

at

much lower cost as compared

to orders cost through phone, mail, or

fax. It also improved

customer

service

in the sense that most parts

could now be delivered the same day or

the next day.

Another

example is of a famous computer selling

brand. It realized that by increasing the

amount of

information

about its customers it was

able to reduce amount of inventory it

should hold. It decided to

share

this information with other

members of the supply chain by allowing

its top suppliers to have

access

to a

secure web site which

informed them about its latest

sales forecasts, planned product

changes or any

warranty

claims etc. It also provided

information about its

customers and their buying

pattern. Thus, it

helped

suppliers to plan their own

production in a much better

way.

The

above examples show how

members of supply chain can

work together to reduce inventory,

increase

quality

of product, reduce production

cost and increase process

speed.

Supply

chain and ultimate consumer

orientation

Primary

objective of supply chain is to help each

company to meet needs of the

consumer at the end of

supply

chain. This approach is

called ultimate consumer orientation. In

1995, a company dealing in

the

business

of production of tiers in America adopted a

different approach by shifting

its focus on tire

dealers

from

ultimate customers. It created an extranet

that allowed tire dealers to

access tire

specifications,

inventory

status and promotional

information on the web. Thus, it

gave opportunity to dealers to

access

product

information directly and

immediately. It also saved

money since a web page is

less expensive than

answering

thousands of phone calls daily by the

company. This initiative

provided a better service to

dealers,

so dealers using this extranet were

not likely to recommend to

customers a tire from the

competing

business.

156

E-COMMERCE

IT430

VU

Competitive

Strategy

Ability

of an organization to prosper arises from

its competitive advantage

over other

organizations

operating

within its market sector.

The strategy of a business to

achieve this goal of competitive

advantage

is

known as competitive strategy. Three

basic strategies for

competitive advantage are as

under:

Cost

leadership

Differentiation

Focus

Cost

leadership

It is the

ability to sell the goods or

provide the service at a price

that is lower than that of

competitors, and

thus

attract more

customers.

Differentiation

Differentiation

means that your

product/service has certain

quality that makes it more

attractive than the

one

offered by your competitor,

despite the price of your competitor's

product/service is somewhat lower.

For

instance, you can beat

your competitors for the reason

that the air conditioner produced by

your

company

is unique as it does not produce noise

while in operation, whereas this

feature is missing in the air

conditioners

produced by your competitors.

Focus

Focus

strategy is defined as concentration on a

single aspect of the market.

That single aspect can be

a

particular

market segment or market

area or product type. For

example, if my competitors are focusing

on

different

market areas, I may, on the

other hand, plan that I can

be more profitable by concentrating on

one

particular

area. It may be a particular province or

a city etc. where I may

have a better distribution

channel.

Role

of e-commerce in Competitive Strategy

By

applying EC following major

benefits can be

derived:

Reduced

administration/transaction

cost

Since

things can be done electronically, so infrastructure or

overhead cost (cost of

building, staff, stationary

etc)

is reduced. Similarly, you can

sell directly to your

customers and it eliminates the

cut/revenue payable to

intermediaries

or dealers. Thus, EC helps in

achieving cost

leadership.

Improved

logistics supply chain

Using EC

one can have a quick

response to the order placed. In

other words, just in time

delivery of the

material

is possible. It helps in reducing

inventory and overall

production cost and

achieving cost

leadership/differentiation.

Customization

With

the help of EC, customer data

can be gathered and

analyzing it customers can be

served in a better

manner

according to their needs. One

can, thus, implement differentiation

and focus strategy.

Differentiate

a product in terms of quality of

service

For

example, online business of

sale of music or books etc. In

such cases delivery time and

transaction cost

is

saved as customers can

directly download the product

from the web site, thus, it

helps in achieving

cost

leadership

and differentiation.

157

Table of Contents:

- E-COMMERCE

- WHAT IS A NETWORK

- HOW MANY CLASS A, B, C NETWORKS AND HOSTS ARE POSSIBLE

- NETWORKING DEVICES

- BASICS OF HTML 1

- BASICS OF HTML 2

- TEXT BOXES, CHECK BOXES, RADIO BUTTONS

- FRAMES AND IMAGES IN HTML

- TAG ATTRIBUTES, SOUNDS FILES, ANIMATIONS

- STYLE SHEETS 1

- STYLE SHEETS 2

- SOME USEFUL STYLE SHEETS PROPERTIES

- JAVA SCRIPTING 1

- JAVA SCRIPTING 2

- JAVA SCRIPTING 3

- JAVA SCRIPTING AND XML

- CLIENT AND SERVER SIDE PROCESSING OF DATA

- APPLETS, CGI SCRIPTS

- MAINTAINING STATE IN A STATELESS SYSTEM

- INTEGRATION WITH ERP SYSTEMS

- FIREWALLS

- CRYPTOGRAPHY

- HASH FUNCTION AND MESSAGE DIGEST

- SYMMETRIC KEY ALGORITHMS

- VIRTUAL PIN PAYMENT SYSTEM

- E-CASH PAYMENT SYSTEM 1

- E-CASH PAYMENT SYSTEM 2

- SECURE SOCKET LAYER (SSL)

- E-BUSINESS: DISADVANTAGES OF E-BUSINESS

- E-BUSINESS REVENUE MODELS

- E-MAIL MARKETING

- CUSTOMER RELATIONSHIP MANAGEMENT (CRM)

- META INFORMATION

- DATA MINING

- CONFIDENCE AND SUPPORT

- ELECTRONIC DATA INTERCHANGE (EDI)

- PERSONAL FINANCE ONLINE

- SUPPLY CHAIN

- PORTER’S MODEL OF COMPETITIVE RIVALRY

- BARRIERS TO INTERNATIONAL E-COMMERCE

- ELECTRONIC TRANSACTIONS ORDINANCE, 2002 - 1

- ELECTRONIC TRANSACTIONS ORDINANCE, 2002 - 2

- ELECTRONIC TRANSACTIONS ORDINANCE, 2002 - 3

- GLOBAL LEGAL ISSUES OF E-COMMERCE - 1

- GLOBAL LEGAL ISSUES OF E-COMMERCE - 2